Services

Consultancy

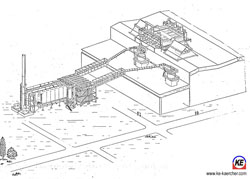

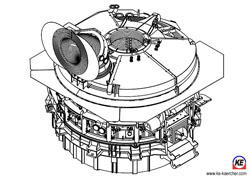

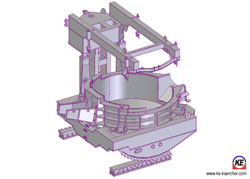

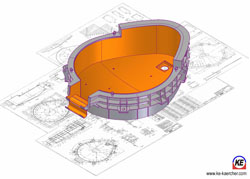

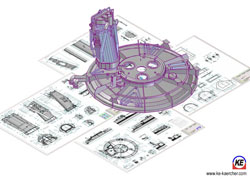

Kaercher Engineering supplies engineered solutions to the steel industry, especially for EAF-melt shops. Our success is in delivering high value added Solutions to our clients resulting in operational efficiencies.

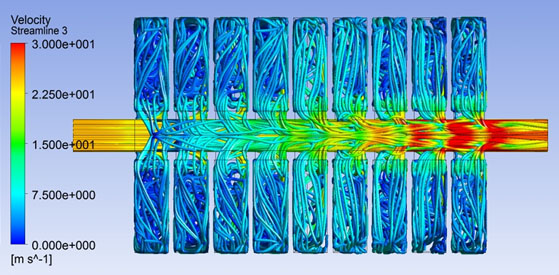

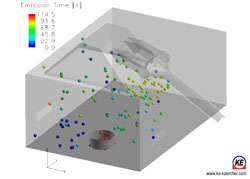

CFD simulation of bag house flow

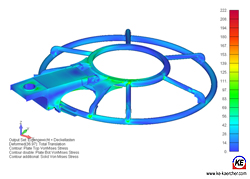

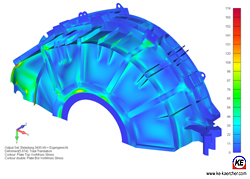

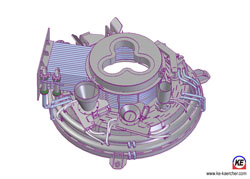

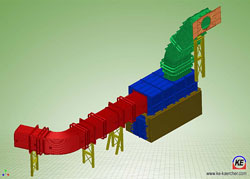

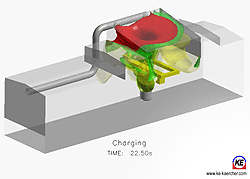

We provide state of the art design using 3D-Modeling, CFD-Simulation of fume gas evacuation systems incl. secondary emission control via canopy hood and last but not least a program that enables us to calculate the entire water flow distribution of complete upper furnace shell, furnace roof and water cooled off-gas systems. According to the input values we calculate all relevant data for the generated off-gas during all Furnace operations to ensure best performance.

As for instance to improve client´s existing de-dusting system and in order to make the right decision for further modifications, we take a site investigation to inspect the present emission control system. During the inspection we measure actual gas flow rates, related gas temperatures and static pressure at several locations, taking in consideration the various EAF operation process. In close liaison with our client we discuss the best and economical solution. We provide a conceptual design including results of our investigation.

top

top back

back home

home e-mail

e-mail imprint

imprint